從 https://forum.onshape.com/discussion/4064/use-opfillet-for-a-sketch 的討論, 我們得知, 目前無法利用 FeatureScript 在繪圖平面中利用 opFillet, 對特定平面圖元進行倒圓角運算, 因此延續上一篇利用漸開線正齒輪輪廓轉換為正齒輪零件, 就必須在實體模型中進行倒圓角運算.

這裡的 FeatureScript 程式碼, 基本架構引用 Onshape 官方正齒輪繪圖 FeatureScript 程式第1版 的內容, 只將推導的漸開線點座標, 透過 skFitSpline 轉為平滑曲線, 但是原版的 offset 參數, 目前只導入 offsetAngle, 以便產生的正齒輪, 可以在組立件中進行囓合.

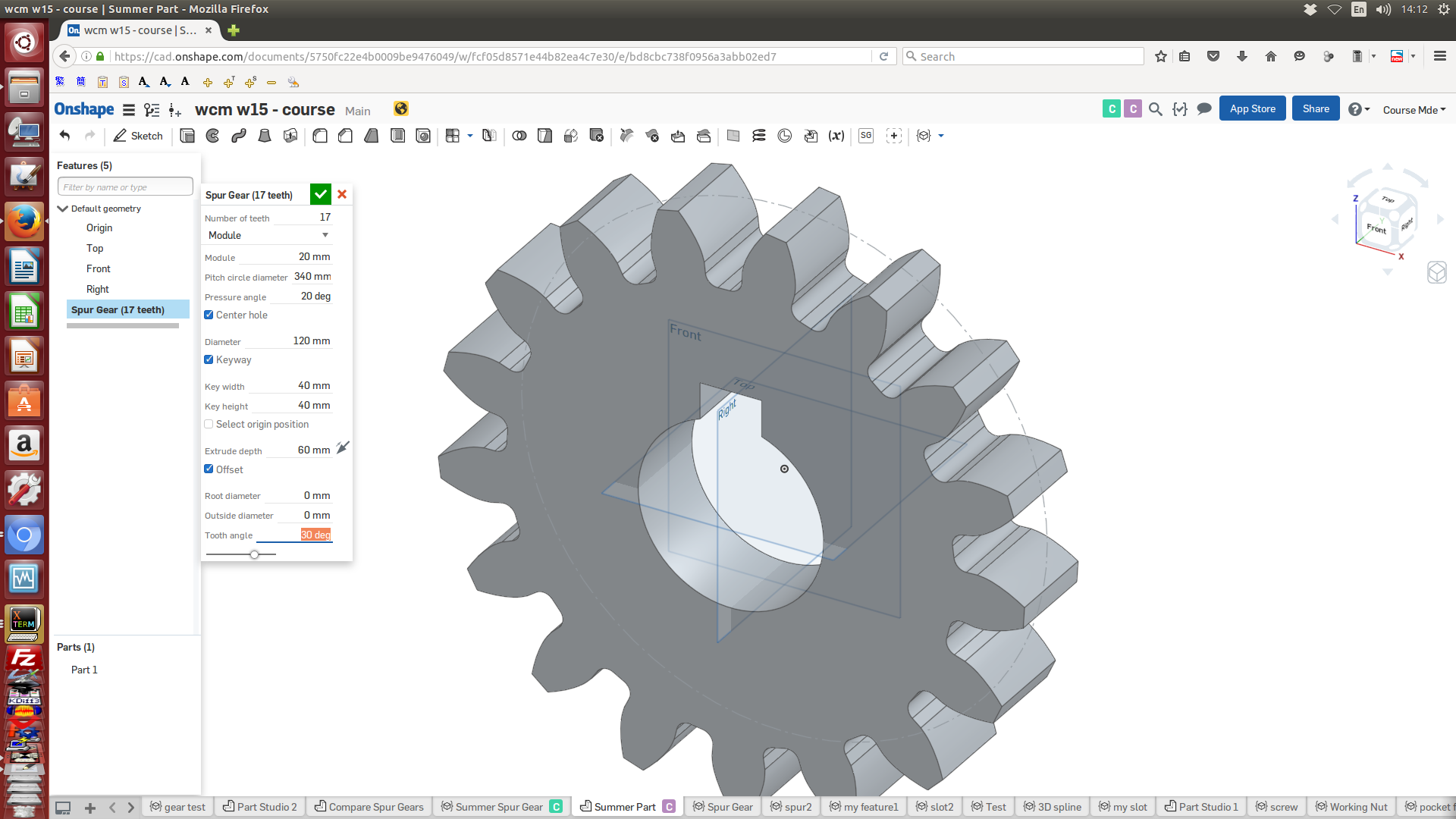

17 齒漸開線正齒輪 FeatureScript 程式繪圖:

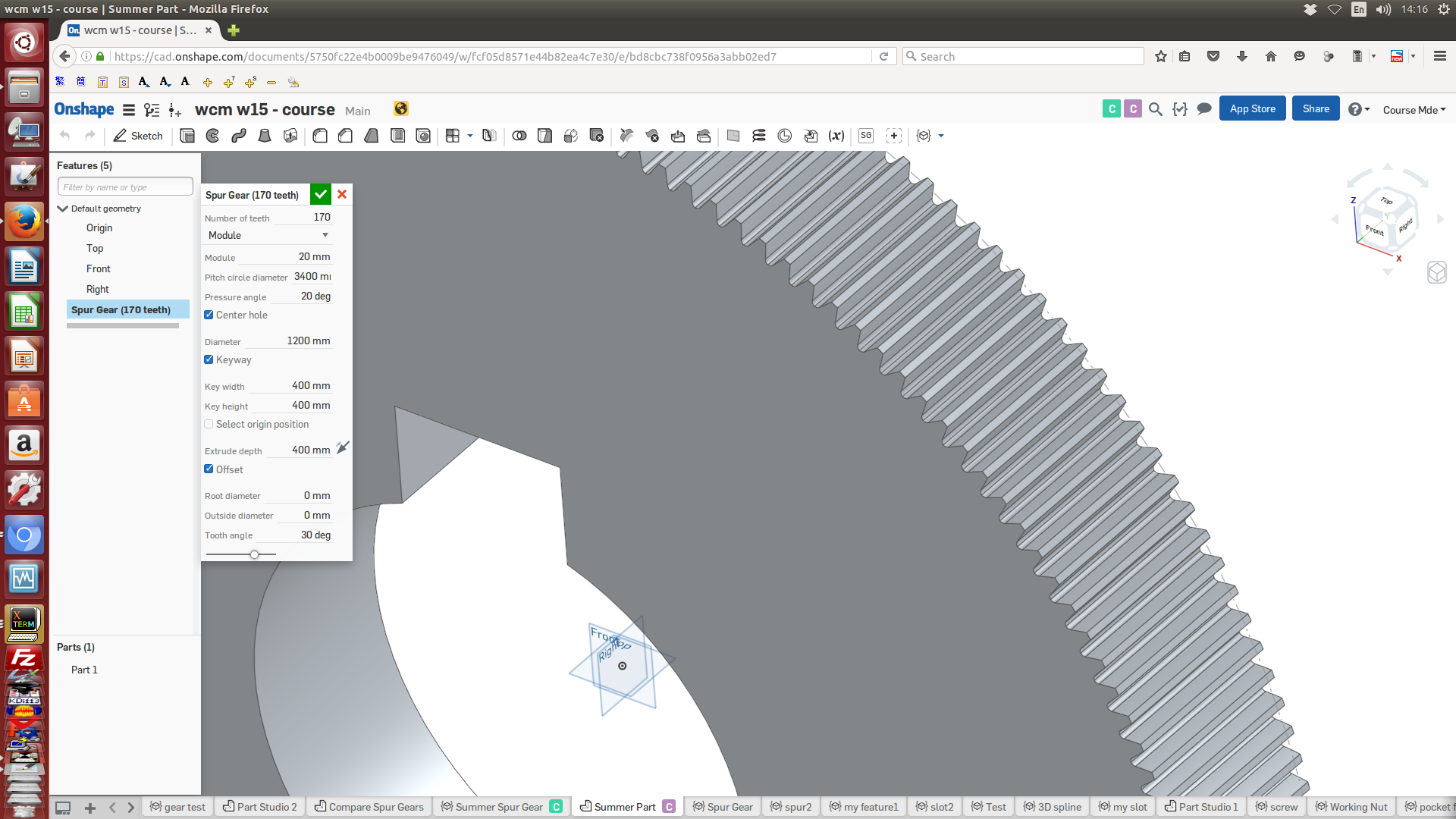

170 齒漸開線正齒輪 FeatureScript 程式繪圖:

2016 Spring 的協同產品設計實習課程, 就要在這個 Onshape FeatureScript 正齒輪零件程式的練習中劃下句點, 下學期的電腦輔助設計實習課程仍將採用 Onshape 與 FreeCAD, 當然 PTC Creo Parametric 年久失修的 Pro/Web.Link 仍可列入參考, 只是 Onshape 加上 FeatureScript 的魅力, 至今沒有其他 MCAD 套件可以比擬, 假如您是隸屬於特定團隊的電腦輔助機械設計工程師, 一定要試試 Onshape, 並且利用 FeatureScript 程式客製化產品開發流程中特定的重要零件. 一旦領略雲端電腦輔助機械設計套件的威力之後, 應該就再也回不去了.

我們當然也知道台灣有許多創新產品開發公司, 至今仍然使用著多年前的 MACD 套件, 忍受著系統更新維護與版本老舊的諸多問題, 假如以購買一套桌上版的商用中端 MCAD 套件, 等於可以連續付月費使用 Onshape 5 年來說, 在日新月異的當下, 5 年前的任何一套 MCAD, 即便功能再強, 也早就應該要更迭換新了, 何況, 檢查一下過去 5 年來工程師為了應付機電整合與製程規劃, 儲存在特定電腦硬碟中的紛亂版本, 將設計研發重心逐步轉換到 Onshape 應該才是解決之道.

以下為上述漸開線正齒輪零件繪圖的 FeatureScript 原始碼:

FeatureScript 355;

import(path : "onshape/std/geometry.fs", version : "355.0");

annotation { "Feature Type Name" : "Summer Spur Gear", "Feature Name Template" : "Spur Gear (#teeth teeth)", "Filter Selector" : "fs", "Editing Logic Function" : "editGearLogic" }

export const SpurGear = defineFeature(function(context is Context, id is Id, definition is map)

precondition

{

annotation { "Name" : "teeth", "UIHint" : "ALWAYS_HIDDEN" }

definition.teeth is string; //used to name the feature only

annotation { "Name" : "Number of teeth" }

isInteger(definition.numTeeth, TEETH_BOUNDS);

annotation { "Name" : "Input type" }

definition.GearInputType is GearInputType;

if (definition.GearInputType == GearInputType.module)

{

annotation { "Name" : "Module" }

isLength(definition.module, MODULE_BOUNDS);

}

if (definition.GearInputType == GearInputType.diametralPitch)

{

annotation { "Name" : "Diametral pitch" }

isReal(definition.diametralPitch, POSITIVE_REAL_BOUNDS);

}

if (definition.GearInputType == GearInputType.circularPitch)

{

annotation { "Name" : "Circular pitch" }

isLength(definition.circularPitch, LENGTH_BOUNDS);

}

annotation { "Name" : "Pitch circle diameter" }

isLength(definition.pitchCircleDiameter, LENGTH_BOUNDS);

annotation { "Name" : "Pressure angle" }

isAngle(definition.pressureAngle, PRESSURE_ANGLE_BOUNDS);

annotation { "Name" : "Center hole" }

definition.centerHole is boolean;

if (definition.centerHole)

{

annotation { "Name" : "Hole diameter" }

isLength(definition.centerHoleDia, CENTERHOLE_BOUNDS);

annotation { "Name" : "Keyway" }

definition.key is boolean;

if (definition.key)

{

annotation { "Name" : "Key width" }

isLength(definition.keyWidth, KEY_BOUNDS);

annotation { "Name" : "Key height" }

isLength(definition.keyHeight, KEY_BOUNDS);

}

}

annotation { "Name" : "Select origin position" }

definition.centerPoint is boolean;

if (definition.centerPoint)

{

annotation { "Name" : "Sketch vertex for center", "Filter" : EntityType.VERTEX && SketchObject.YES, "MaxNumberOfPicks" : 1 }

definition.center is Query;

}

annotation { "Name" : "Extrude depth" }

isLength(definition.gearDepth, BLEND_BOUNDS);

annotation { "Name" : "Extrude direction", "UIHint" : "OPPOSITE_DIRECTION" }

definition.flipGear is boolean;

annotation { "Name" : "Offset" }

definition.offset is boolean;

if (definition.offset)

{

annotation { "Name" : "Root diameter" }

isLength(definition.offsetClearance, ZERO_DEFAULT_LENGTH_BOUNDS);

annotation { "Name" : "Outside diameter" }

isLength(definition.offsetDiameter, ZERO_DEFAULT_LENGTH_BOUNDS);

annotation { "Name" : "Tooth angle" }

isAngle(definition.offsetAngle, ANGLE_360_ZERO_DEFAULT_BOUNDS);

}

}

{

var offsetDiameter = 0 * meter;

var offsetClearance = 0 * meter;

var offsetAngle = 0 * degree;

if (definition.offset)

{

offsetDiameter = definition.offsetDiameter;

offsetClearance = definition.offsetClearance;

offsetAngle = definition.offsetAngle;

}

if (definition.centerHole && definition.centerHoleDia >= definition.pitchCircleDiameter - 4 * definition.module)

{

throw regenError("Center hole diameter must be less than the root diameter", ["centerHoleDia"]);

}

if (definition.key && definition.keyHeight / 2 + definition.centerHoleDia >= definition.pitchCircleDiameter - 4 * definition.module)

{

throw regenError("Center hole diameter plus Key height must be less than the root diameter", ["keyHeight"]);

}

// if no center vertex selected build gear on the front plane at the origin

var location = vector(0, 0, 0) * meter;

var sketchPlane = plane(location, vector(0, -1, 0), vector(1, 0, 0));

var center3D = location;

// else find location of selected vertex and its sketch plane and create a new sketch for the gear profile

if (definition.centerPoint)

{

location = evaluateQuery(context, definition.center)[0];

sketchPlane = evOwnerSketchPlane(context, { "entity" : location });

center3D = evVertexPoint(context, { "vertex" : location });

}

const gearSketch = newSketchOnPlane(context, id + "gearSketch", { "sketchPlane" : sketchPlane });

const center2D = worldToPlane(sketchPlane, center3D);

var filletEdges = [];

var regionPoint;

// 漸開線近似點數

var imax = 5;

// 使用者所選的齒輪圓心 x 座標

var midx = center2D[0];

// 使用者所選的齒輪圓心 y 座標

var midy = center2D[1];

// 齒數

var n = definition.numTeeth;

// 模數

var m = definition.module;

// 壓力角, 單位為角度

var pa = definition.pressureAngle;

// 齒輪的節圓半徑

var rp = m*n/2;

// 正齒輪囓合用的定位線

skLineSegment(gearSketch, "line", {

"start" : vector(midx,midy),

"end" : vector(midx,midy+rp)

});

// 齒根, 暫時不考慮納入 offsetClearance

var d = 2.5*rp/n;

// 齒頂圓半徑, 暫不考慮納入 offsetDiameter

var ra = rp + m;

// 基圓半徑

var rb = rp*cos(pa);

//print(rb);

// 齒根圓半徑

var rd = rp - d;

// 分段後齒頂與齒根半徑差增量

var dr = 0*meter;

// 若 rb > rd 時從基圓開始繪製漸開線, 但是若 rd > rb, 則漸開線從 rd 畫到齒頂圓

if (rd > rb)

{

// 半徑差的分段, 由齒根圓到齒頂圓

dr = (ra-rd)/imax;

}

else

{

// 半徑差的分段, 由基圓到齒頂圓

dr = (ra-rb)/imax;

}

// PI 為實數值沒有單位, tan(pa)也沒有單位, pa 已經設定單位為 degree

var rot = PI/(2*n)*radian;

// 用來設定 entity id 用的增量變數

var nameId = 1;

var r = 0*meter;

// theta 為浮點數字

var theta = 0;

var inv = 0*radian;

var inc = 0*radian;

// 當 r=rp 時 ,計算 inv_rp 用來旋轉漸開線用

// theta 為沒有單位的實數

theta = sqrt((rp*rp)/(rb*rb)-1);

// atan(theta) 為 radian

// Onshape SG 的 const alpha 就是這裡的 inv_rp

// Onshape SG 的 const beta 就是這裡的 rot-inv_rp

var inv_rp = theta*radian-atan(theta);

// 漸開線上點的 x 座標

var xpt = 0*meter;

// 漸開線上點的 y 座標

var ypt = 0*meter;

// 左側漸開線第1點座標 left first x and y

var lfx = 0*meter;

var lfy = 0*meter;

// 右側漸開線第1點座標 right first x and y

var rfx = 0*meter;

var rfy = 0*meter;

// 左側齒根圓上點座標 left x of dedendum point

var lxd = 0*meter;

var lyd = 0*meter;

// 右側齒根圓上點座標 right x of dedendum point

var rxd = 0*meter;

var ryd = 0*meter;

// 左側齒根圓上點座標 right x of dedendum point (advanced)

var lxd_ad = 0*meter;

var lyd_ad = 0*meter;

var inc_ad = 0*radian;

for (var j=0;j<n;j+=1)

{

var involute1 = [];

var involute2 = [];

var arcDone = false;

var point1;

var point2;

// 當 j 增量時, 按照齒數輪廓繞行旋轉增量角度, 加入 offsetAngle 參數

inc = (2.*j*PI/n)*radian+offsetAngle;

inc_ad = (2.*(j+1)*PI/n)*radian+offsetAngle;

if (rd>rb)

{

// 當齒根半徑因為齒數增多後大於基圓半徑時, 漸開線從齒根圓長起

theta = sqrt((rd*rd)/(rb*rb)-1.);

inv = theta*radian-atan(theta);

// 左側漸開線第1點座標

// 左側輪廓線配合逆時針旋轉 inc 角度

lfx = midx+rd*sin(inv-rot-inv_rp+inc);

lfy = midy+rd*cos(inv-rot-inv_rp+inc);

point1 = vector(lfx, lfy);

lxd = lfx;

lyd = lfy;

lxd_ad = midx+rd*sin(inv-rot-inv_rp+inc_ad);

lyd_ad = midy+rd*cos(inv-rot-inv_rp+inc_ad);

// 右側漸開線第1點座標

// 右側輪廓線配合順時針旋轉 inc 角度

rfx = midx-rd*sin(inv-rot-inv_rp-inc);

rfy = midy+rd*cos(inv-rot-inv_rp-inc);

point2 = vector(rfx, rfy);

rxd = rfx;

ryd = rfy;

}

else

{

// 當基圓半徑大於齒根圓時, 漸開線從基圓長起

//theta = sqrt((rb*rb)/(rb*rb)-1.);

theta = 0;

inv = theta*radian-atan(theta);

// 左側漸開線第1點座標

lfx = midx+rb*sin(inv-rot-inv_rp+inc);

lfy = midy+rb*cos(inv-rot-inv_rp+inc);

point1 = vector(lfx, lfy);

lxd = midx+rd*sin(inv-rot-inv_rp+inc);

lyd = midy+rd*cos(inv-rot-inv_rp+inc);

lxd_ad = midx+rd*sin(inv-rot-inv_rp+inc_ad);

lyd_ad = midy+rd*cos(inv-rot-inv_rp+inc_ad);

// 左側從基圓點到齒根圓點, 畫直線 left from base point to dedendum point

skLineSegment(gearSketch, "line_lbd" ~ nameId, {

"start" : vector(lfx,lfy),

"end" : vector((lxd),(lyd))

});

// 右側漸開線第1點座標

rfx = midx-rb*sin(inv-rot-inv_rp-inc);

rfy = midy+rb*cos(inv-rot-inv_rp-inc);

point2 = vector(rfx, rfy);

rxd = midx-rd*sin(inv-rot-inv_rp-inc);

ryd = midy+rd*cos(inv-rot-inv_rp-inc);

// 右側從基圓點到齒根圓點, 畫直線 right from base point to dedendum point

skLineSegment(gearSketch, "line_rbd" ~ nameId, {

"start" : vector(rfx,rfy),

"end" : vector((rxd),(ryd))

});

}

// 處理齒根的圓弧

if (!arcDone) // create base arc between involutes once per tooth

{

var mid = getArcMidPoint(center2D, vector(lxd_ad,lyd_ad), vector(rxd,ryd)); // sketch arc is arc 3 points so need addtional point on arc

if (mid != undefined) // if no base cylinder present (due to pressure angle), don't draw it

{

// 齒根圓上的圓弧

skArc(gearSketch, "arc-d" ~ nameId, {

"start" : vector(lxd_ad,lyd_ad),

"mid" : mid,

"end" : vector(rxd,ryd)

});

}

if (rd>rb)

{

// 只有在齒根圓半徑大於基圓時, 將漸開線起點作為倒圓角的基準點

// find points in 3D space where edges need to be filleted later

filletEdges = append(filletEdges, toWorldVector(planeToCSys(sketchPlane), point2, definition.gearDepth, definition.flipGear));

filletEdges = append(filletEdges, toWorldVector(planeToCSys(sketchPlane), point1, definition.gearDepth, definition.flipGear));

}

else

{

// 當小齒數時, 從基圓到齒根圓有一條直線, 因此倒圓角基準點必須以齒根圓上的點為基準

// find points in 3D space where edges need to be filleted later

filletEdges = append(filletEdges, toWorldVector(planeToCSys(sketchPlane), vector(rxd, ryd), definition.gearDepth, definition.flipGear));

filletEdges = append(filletEdges, toWorldVector(planeToCSys(sketchPlane), vector(lxd, lyd), definition.gearDepth, definition.flipGear));

}

// find area to extrude

regionPoint = vector(point1[0] * 0.95 + center2D[0]*0.05, point1[1] * 0.95+center2D[1]*0.05, 0 * meter);

arcDone = true;

}

// 將漸開線第1點存入 involute1 與 involute2 陣列中

involute1 = append(involute1, point1);

involute2 = append(involute2, point2);

for (var i=1; i<imax+1; i+= 1)

{

// 先處理中線左側的漸開線

// 當 rd 大於 rb 時, 漸開線並非畫至 rb, 而是 rd

if (rd>rb)

{

r = rd+i*dr;

}

else

{

r = rb+i*dr;

}

theta = sqrt((r*r)/(rb*rb)-1);

var inv = theta*radian-atan(theta);

// 漸開線上的點座標

xpt = midx+r*sin(inv-rot-inv_rp+inc);

ypt = midy+r*cos(inv-rot-inv_rp+inc);

point1 = vector(xpt, ypt);

// 更新漸開線點座標

lfx = xpt;

lfy = ypt;

//nameId += 1;

involute1 = append(involute1, point1);

}

// 紀錄左側漸開線的最後一點, 也就是齒頂圓上的點座標

var lastlx = xpt;

var lastly = ypt;

// another side

for (var i=1; i<imax+1; i+= 1)

{

if (rd>rb)

{

r = rd+i*dr;

}

else

{

r = rb+i*dr;

}

theta = sqrt((r*r)/(rb*rb)-1);

var inv = theta*radian-atan(theta);

// 漸開線上的點座標

xpt = midx-r*sin(inv-rot-inv_rp-inc);

ypt = midy+r*cos(inv-rot-inv_rp-inc);

point2 = vector(xpt, ypt);

// 更新漸開線點座標

rfx = xpt;

rfy = ypt;

//nameId += 1;

involute2 = append(involute2, point2);

}

var lastrx = xpt;

var lastry = ypt;

// create involute sketch splines

skFitSpline(gearSketch, "spline-a" ~ nameId, {

"points" : involute1

});

skFitSpline(gearSketch, "spline-b" ~ nameId, {

"points" : involute2

});

// 要注意, 若對調 vector(lastrx, lastry) 與 vector(lastlx, lastly) 則無法求得中點

var mid_a = getArcMidPoint(center2D, vector(lastrx,lastry), vector(lastlx,lastly));

if (mid_a != undefined)

{

skArc(gearSketch, "arc-a" ~ nameId, {

"start" : vector(lastlx,lastly),

"mid" : mid_a,

"end" : vector(lastrx,lastry)

});

}

nameId += 1;

}

if (definition.centerHole)

{

if (definition.key)

{

var keyVector = vector(0, 1);

var perpKeyVector = vector(-1, 0);

var keyHeight = (definition.keyHeight + definition.centerHoleDia) / 2;

var points = [

center2D - (definition.keyWidth / 2) * perpKeyVector,

center2D - (definition.keyWidth / 2) * perpKeyVector + keyHeight * keyVector,

center2D + (definition.keyWidth / 2) * perpKeyVector + keyHeight * keyVector,

center2D + (definition.keyWidth / 2) * perpKeyVector];

for (var i = 0; i < size(points); i += 1)

{

skLineSegment(gearSketch, "line" ~ nameId,

{ "start" : points[i],

"end" : points[(i + 1) % size(points)]

});

nameId += 1;

}

}

// center hole circle sketch

skCircle(gearSketch, "Center", {

"center" : center2D,

"radius" : definition.centerHoleDia / 2

});

}

skSolve(gearSketch);

extrude(context, id + "extrude1", {

"entities" : qContainsPoint(qCreatedBy(id + "gearSketch", EntityType.FACE), toWorld(planeToCSys(sketchPlane), regionPoint)),

"endBound" : BoundingType.BLIND,

"depth" : definition.gearDepth,

"oppositeDirection" : definition.flipGear

});

var filletEdges3D = [];

for (var i = 0; i < size(filletEdges); i += 1)

{

// Find the edges that intersect the points previously collected

filletEdges3D = append(filletEdges3D, qContainsPoint(qCreatedBy(id + "extrude1", EntityType.EDGE), filletEdges[i]));

}

const filletRadius = norm(filletEdges[1] - filletEdges[0]) / 4; // arbitrary fillet size = one fourth the distance between the edges

if (filletRadius >= 0.2 * millimeter) // arbitrary small size assuming tooling cannot hold a fillet radius smaller than this

{

try(opFillet(context, id + "fillet1", {

"entities" : qUnion(filletEdges3D),

"radius" : filletRadius

}));

}

// Remove sketch entities - no longer required

opDeleteBodies(context, id + "delete", { "entities" : qCreatedBy(id + "gearSketch") });

// created PCD sketch

const PCDSketch = newSketchOnPlane(context, id + "PCDsketch", { "sketchPlane" : sketchPlane });

skCircle(PCDSketch, "PCD", {

"center" : center2D,

"radius" : definition.pitchCircleDiameter / 2,

"construction" : true

});

skSolve(PCDSketch);

});

function getArcMidPoint(center is Vector, start is Vector, end is Vector)

{

// need to convert 2D vectors back to 3D for vector angle calculation

const center3D = vector(center[0], center[1], 0 * meter);

const start3D = vector(start[0], start[1], 0 * meter);

const end3D = vector(end[0], end[1], 0 * meter);

const angle = vectorAngle(center3D - start3D, center3D - end3D) / 2;

// if angle is less than zero then arc was flipped

if (angle <= 0 * radian)

return;

start = center - start;

var ca = cos(angle); // in radians

var sa = sin(angle);

return center - vector(ca * start[0] - sa * start[1], sa * start[0] + ca * start[1]);

}

function vectorAngle(vector1 is Vector, vector2 is Vector)

{

// function assumes vectors are on a 2D plane so Z is always zero and the normal vector is always [0, 0, 1]

return atan2(dot(vector(0, 0, 1), cross(vector1, vector2)), dot(vector1, vector2));

}

function toWorldVector(csys is CoordSystem, point is Vector, depth is map, direction is boolean) returns Vector

{

var dir = direction ? -1 : 1;

var vector3D = vector(point[0], point[1], dir * depth / 2);

return toWorld(csys, vector3D);

}

export function editGearLogic(context is Context, id is Id, oldDefinition is map, definition is map, isCreating is boolean, specifiedParameters is map, hiddenBodies is Query) returns map

{

// isCreating is required in the function definition for edit logic to work when editing an existing feature

if (oldDefinition.numTeeth != definition.numTeeth)

{

definition.module = definition.pitchCircleDiameter / definition.numTeeth;

definition.circularPitch = definition.module * PI;

definition.diametralPitch = 1 * inch / definition.module;

definition.teeth = toString(definition.numTeeth); //to name the feature

return definition;

}

if (oldDefinition.circularPitch != definition.circularPitch)

{

definition.module = definition.circularPitch / PI;

definition.pitchCircleDiameter = (definition.circularPitch * definition.numTeeth) / PI;

definition.diametralPitch = 1 * inch / definition.module;

return definition;

}

if (oldDefinition.pitchCircleDiameter != definition.pitchCircleDiameter)

{

definition.module = definition.pitchCircleDiameter / definition.numTeeth;

definition.circularPitch = (PI * definition.pitchCircleDiameter) / definition.numTeeth;

definition.diametralPitch = 1 * inch / definition.module;

return definition;

}

if (oldDefinition.module != definition.module)

{

definition.circularPitch = definition.module * PI;

definition.pitchCircleDiameter = definition.numTeeth * definition.module;

definition.diametralPitch = 1 * inch / definition.module;

return definition;

}

if (oldDefinition.diametralPitch != definition.diametralPitch)

{

definition.circularPitch = PI / (definition.diametralPitch / inch);

definition.module = definition.circularPitch / PI;

definition.pitchCircleDiameter = (definition.circularPitch * definition.numTeeth) / PI;

return definition;

}

return definition;

}

const TEETH_BOUNDS =

{

"min" : 4,

"max" : 250,

(unitless) : [4, 25, 250]

} as IntegerBoundSpec;

const PRESSURE_ANGLE_BOUNDS =

{

"min" : 12 * degree,

"max" : 35 * degree,

(degree) : [12, 20, 35]

} as AngleBoundSpec;

const MODULE_BOUNDS =

{

"min" : -TOLERANCE.zeroLength * meter,

"max" : 500 * meter,

(meter) : [1e-5, 0.001, 500],

(centimeter) : 0.1,

(millimeter) : 1.0,

(inch) : 0.04

} as LengthBoundSpec;

const CENTERHOLE_BOUNDS =

{

"min" : -TOLERANCE.zeroLength * meter,

"max" : 500 * meter,

(meter) : [1e-5, 0.01, 500],

(centimeter) : 1.0,

(millimeter) : 10.0,

(inch) : 0.375

} as LengthBoundSpec;

const KEY_BOUNDS =

{

"min" : -TOLERANCE.zeroLength * meter,

"max" : 500 * meter,

(meter) : [1e-5, 0.003, 500],

(centimeter) : 0.3,

(millimeter) : 3.0,

(inch) : 0.125

} as LengthBoundSpec;

export enum GearInputType

{

annotation { "Name" : "Module" }

module,

annotation { "Name" : "Diametral pitch" }

diametralPitch,

annotation { "Name" : "Circular pitch" }

circularPitch

}